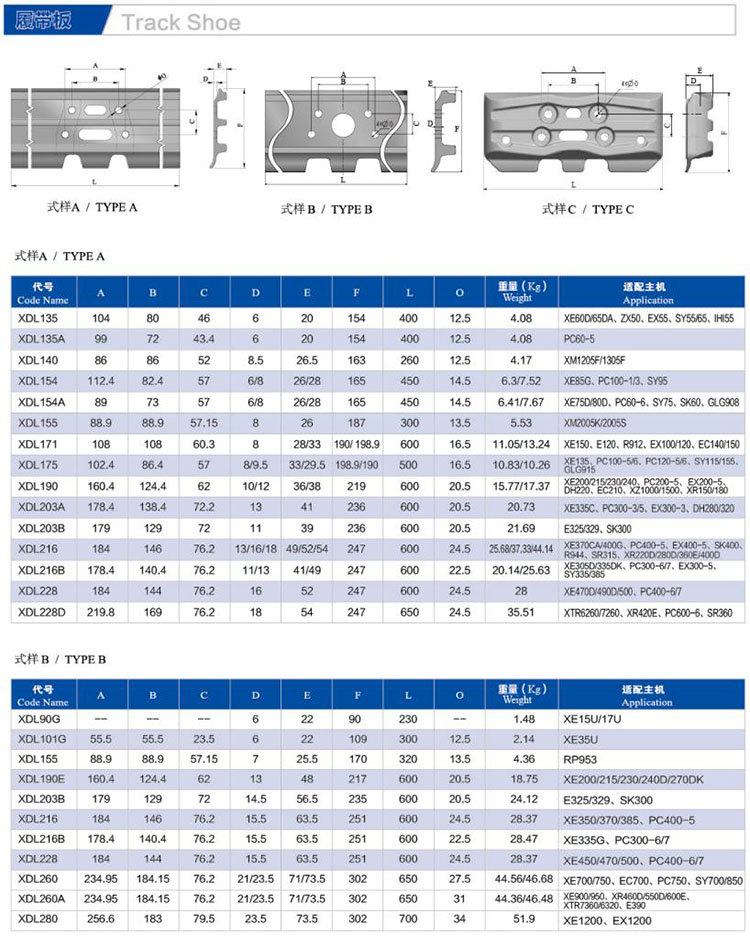

Product Highlights:

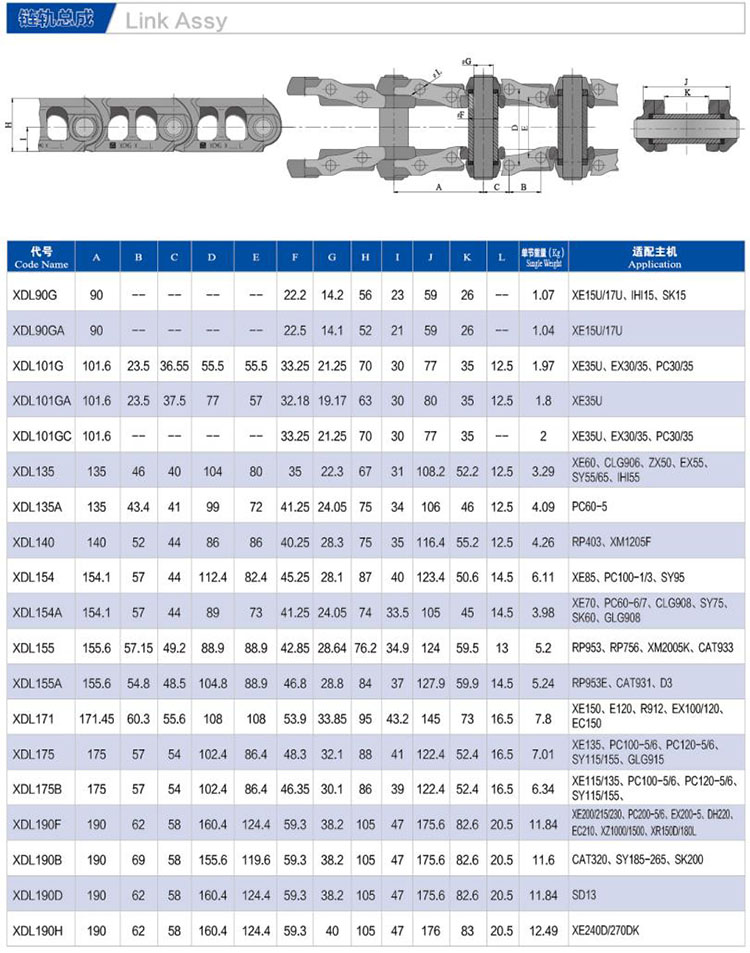

1. According to different host types and working conditions, the mud leakage holes of the track shoe are designed to reduce the damage to the track by external hard objects and improve the service life of the track shoe;

2. The tread of the chain track adopts continuous induction hardening and tempering technology, and the depth of the hardened layer and the surface hardness of the forging are uniform;

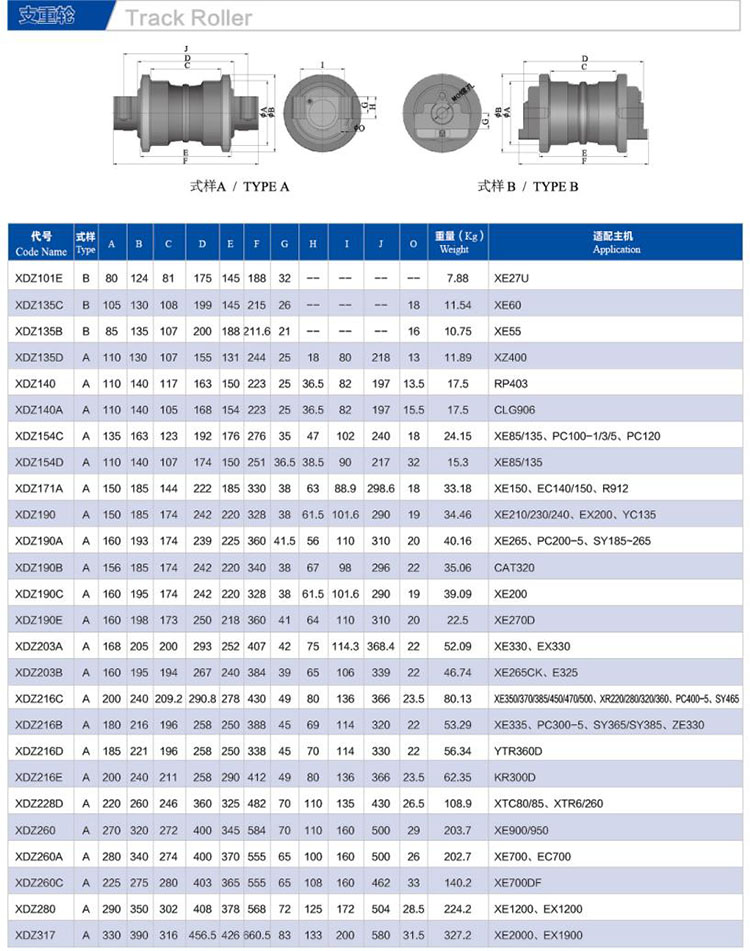

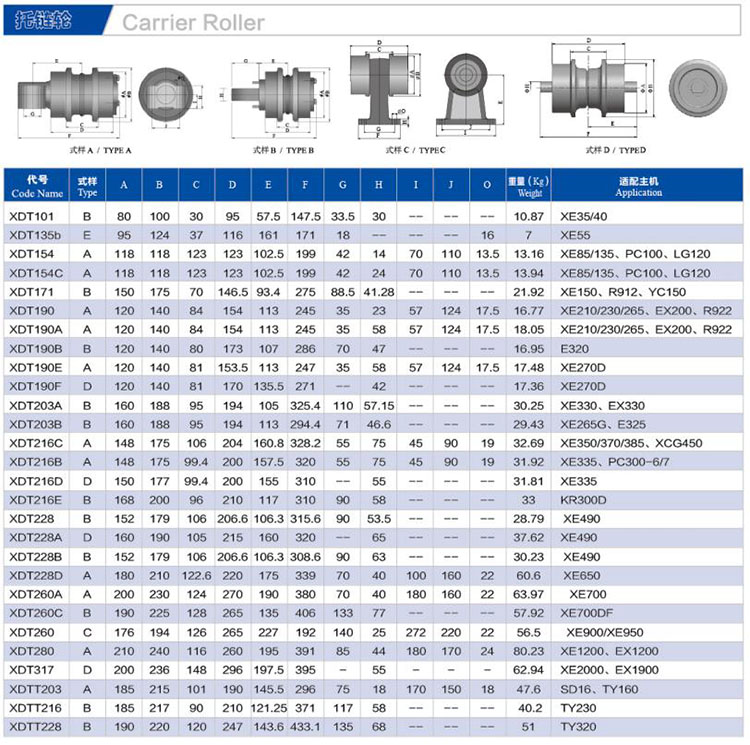

3. Track Roller semi-wheel body adopts fully automatic closed forging forming technology. By optimizing the mold structure and forging process, it solves the problems of forging folding and lack of meat and ensures the stability of product process quality;

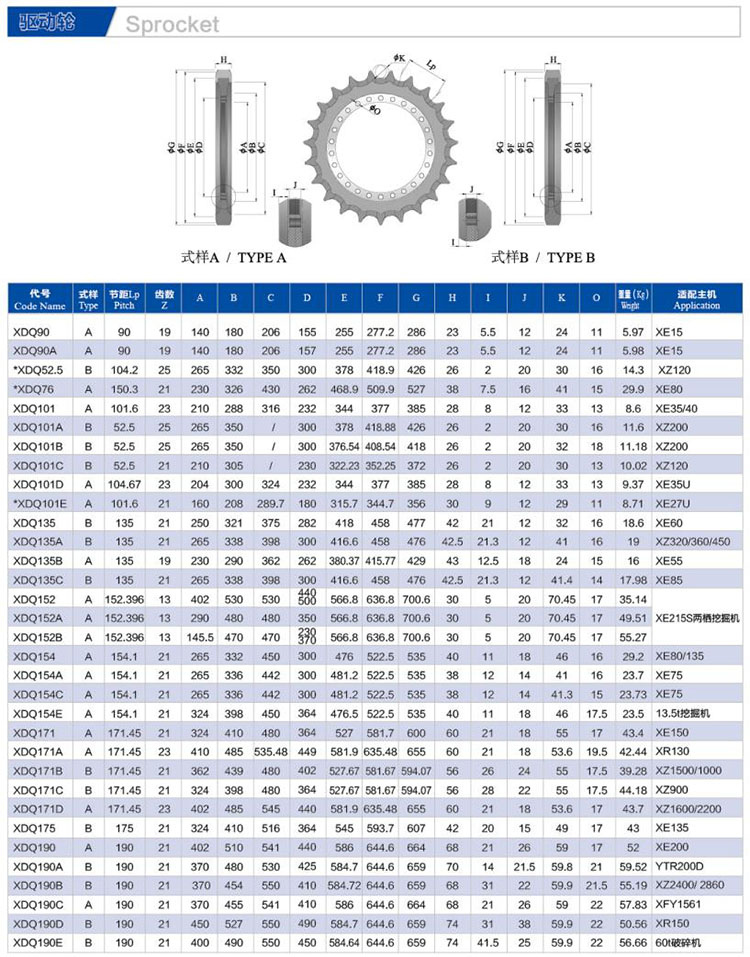

4. The sprocket body adopts fully automatic closed forging forming technology, and through optimizing the mold structure and forging process, it solves the problems of forging folding, lack of meat and other industries;

5. Large-tonnage mine Idler shaft seat is made of cast alloy steel and normalized. The strength of the matrix is 25% higher than that of traditional ductile iron materials, and the elongation is 50% higher than that of ductile iron materials.

6. The surface hardened layer of the Sprocket has uniform structure and refined grains, the matrix has good toughness and strength, and the tooth surface has high wear resistance.

uMore Excavator Accessory